16S55A-1800W Battery Management System protective plate For

Electric Vehicle

1. Functional Features

High-integrated analog front-end Adjustable overcurrent protection

Isolation of the power supply circuit Has a variety of dormancy and

awakening modes

Integrated serial port IC Low power consumption

High Voltage Accuracy (≤10mV) RS485 Communication

High Current Accuracy (≤2%@FS) Adjustable Parameter Settings

4-Way Battery Temperature Detection (≤2°C) Data Refresh Interval

(Period) ≤ 2 Seconds

SOC Estimation Function LED Status Indication Function

SOH Estimation Function Charge Equalization Function

Short Circuit Protection Function SOC Accuracy (≤5% @ 50% Capacity

Range Or More)

2. Functional Block Diagram

3. Environmental Requirements

| Projects | Parameters | Unit |

| Operating Temperature | -23 to 60 | ℃ |

| Storage Temperature | -40 to 75 | ℃ |

| Operating Humidity | ≤95 (45°C±2°C) | %RH |

| Storage Humidity | ≤95 (45°C±2°C) | %RH |

| Temperature Measurement | -40 to 125 | ℃ |

| Atmospheric Pressure | 70~106 | kPa |

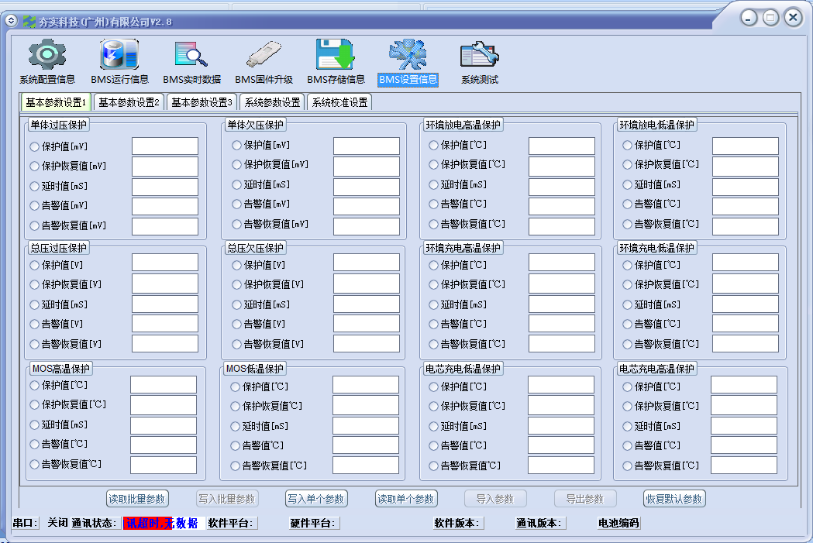

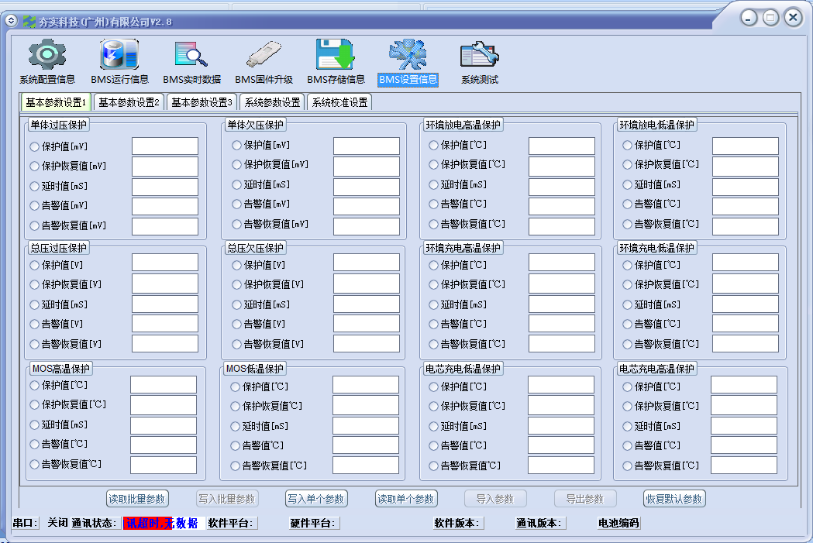

4.The BMS setup interface

5.Note for installing the protective plate:

1) First connect the communication port CN1 or CN3 according to the

wiring diagram of the protection board;

2) Connect the total negative electrode of the cell to the B-of the

protection plate;

3) Connect the total positive electrode of the cell to the B +

terminal of the protection plate;

4) Connect the cell

B0.B1.B2.B3.B4.B5.B6.B7.B8.B9.B10.B11.B12.B13.B14.B15.B16 to the

protection plate 1 # / 2 #;

5) The negative electrode of the load / charger is directly

connected to the positive electrode of the protection plate P-;

6) The positive electrode of the load / charger is directly

connected to the positive electrode P + of the protection plate;

7) Charging activation / communication activation;

6.Step of removing the protective plate:

1) Remove the communication port CN1 or CN3;

2) Remove the connection line of the P + load / charger positive

electrode on the protection plate;

3) Remove the connection cable of the P-load / charger anode on the

protection board;

4) Remove the cell

B16.B15.B14.B13.B12.B11.B10.B9.B8.B7.B6.B5.B4.B3.B2.B1.B0 on the

protective plate in sequence;

5) Remove the total positive B + connection line of the cell;

6) Finally, remove the connecting line of the total negative B-of

the cell;

7.Precautions for use:

1) When connecting the battery lead, note not to misconnect or

reverse connect. If the wrong lead is connected, it may cause

damage to this circuit board, which should be re-tested again

before use.

2) When assembly, the protective plate is careful not to directly

contact the surface of the cell to avoid damage to the cell. Ensure

the assembly.

3) In the process of use, pay attention to the lead head, soldering

iron, solder and other components do not touch the components on

the circuit board, otherwise it may lead to damage to the

protection board.

4) The use process should pay attention to anti-static,

moisture-proof, waterproof and other measures.

5) Please follow the designed parameters and the conditions of use

during the use process, and do not exceed the relevant values in

this specification, otherwise it may lead to damage to the

protection plate.

6) After combining the battery pack and the protection panel, if

there is no voltage output or no charge for the first time, please

re-check whether the wiring is correct.